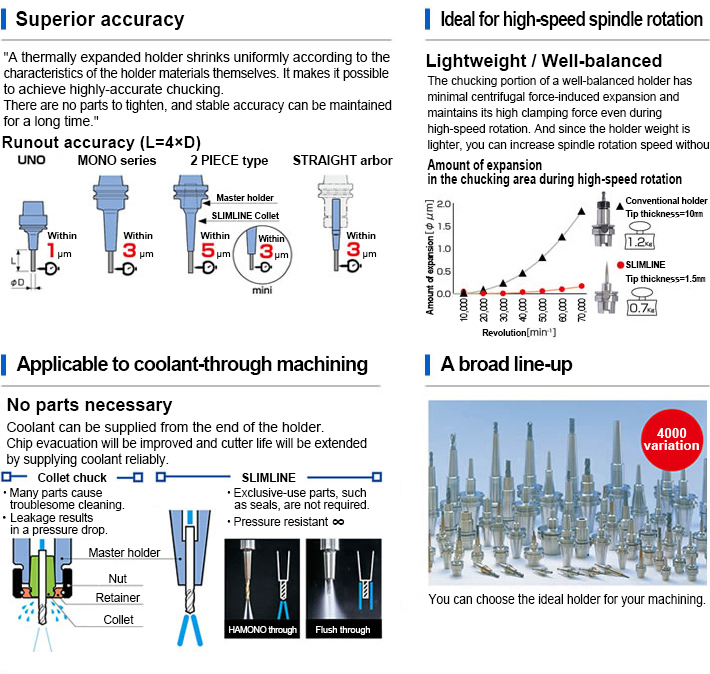

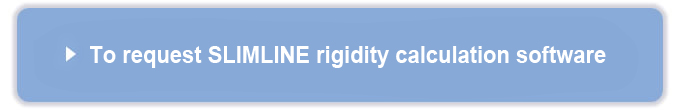

Features of Shrink-fit holder SLIMLINE

![]()

and Simple Design!

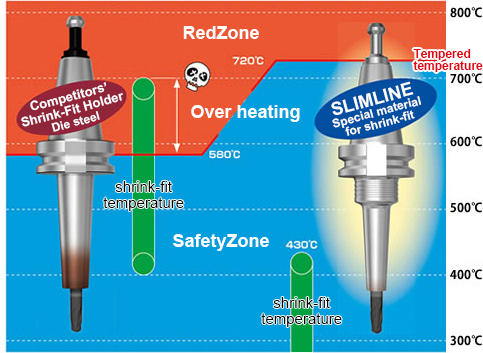

| ▶No over heating

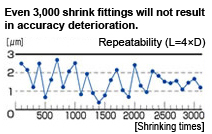

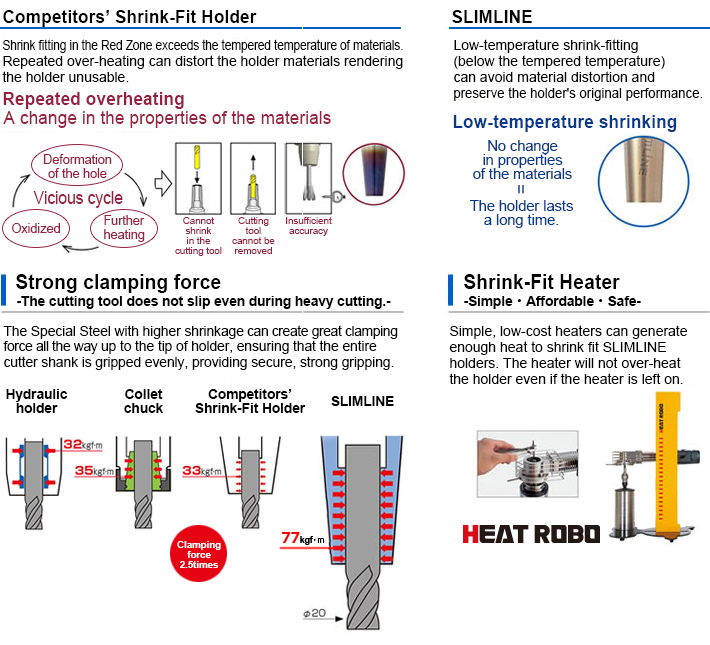

Low-temperature shrinking. Prevent accuracy loss due to over-heating. Special steel with higher shrinkage grips the entire cutter shank evenly! Slim nose allows access to hard-to-reach areas! Over 4,000 variations!

|

|

|

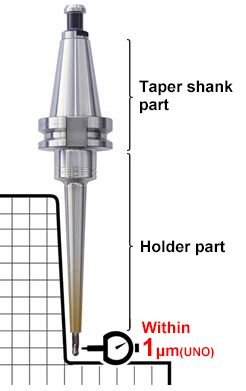

Taper shank parts, which attach to the MC, are made of carbon steel. The cutter clamping portion is made of special steel with higher-than-normal coefficient of thermal expansion. A hybrid holder made of different materials with functions that meet user needs. |

The MST’s unique, “special steel for exclusive use in shrink fitting”has been adopted in the materials of SLIMLINE shrink-fit holders. It has a high coefficient of thermal expansion.

“Low-temperature shrink fitting” is available at 300゚C.SLIMLINE holders provide “high clamping force”, “long life” and “chucking of small-diameter cutting tools”.

No breaking -Shrink-fit at lower temperature than it’s tempered temperature, not damaging materials.- |

|||

|

A MST’s special steel for exclusive use in shrink fit holders has a very large coefficient of thermal expansion (1.6 times greater than that of other companies), and it has superior heat resistance. It is an expansive material and achieves low-temperature shrink fitting at 300℃ (430℃ maximum). There is no need to worry about the deformation of the holder materials due to overheating. The stable performance of MST’s special steel can be demonstrated indefinitely in small-diameter holes, in which higher heating temperatures are needed. |

|

||

|

|||

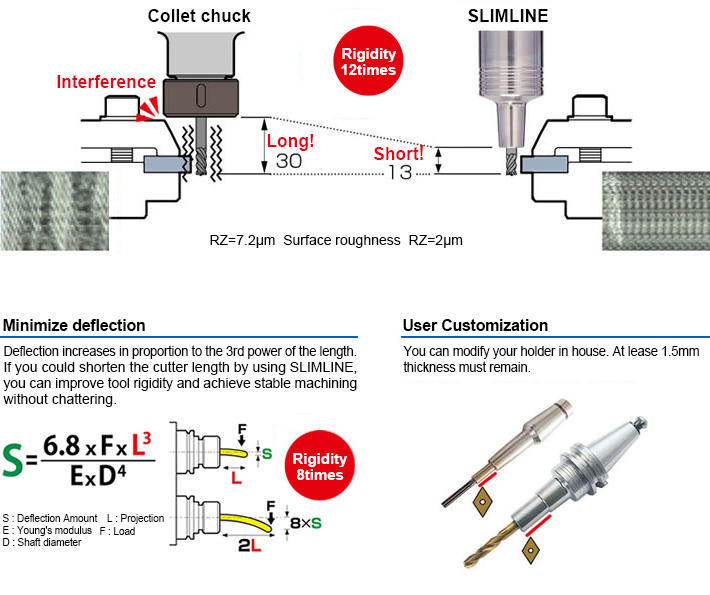

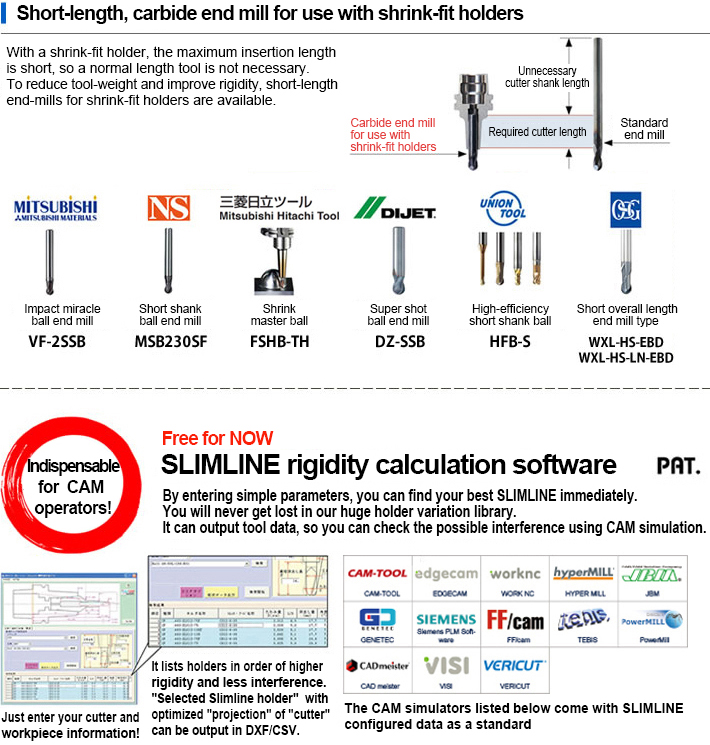

Super slim design -Extra slimness expands the machining area-

There is no interference with workpieces or jig fixtures. The holder can approach very close to a workpiece. Cutting tool overhang can be set to the shortest length.

If a holder is elongated and tool overhang is shortened, this makes it possible to perform strong, stable machining by minimizing the amount of a tool deflection.

| Cutter shank dia. |

Φ3 | Φ4 | Φ6 | Φ10 | … |

| Holder dia. (SLIM type) |

Φ6 | Φ7 | Φ9 | Φ13 | … |