HYPER VERSION

![]()

For heavy-duty end-mill machining

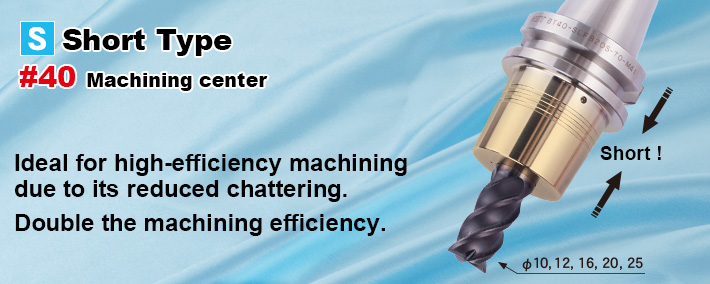

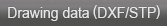

For high-speed spindle machining centers Short type

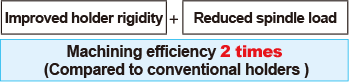

By minimizing the holder length, the machining

efficiency is now double that of conventional holders.

Even for heavy-duty machining with compact machining centers,

it reduces spindle load and prevents fretting corrosion

of the holder shank.

Shortening the tool projection by using a short flute length

cutting tool leads to more efficient machining.

Recommended tools for short type

| OSG | WX-PHSS(General purpose)、UP-PHS(General purpose) |

| DIJET | DV-OCSAR(For difficult-to-machine materials)、AL-SEESS(For aluminum alloy) |

| TUNGALOY | SEF4000(For difficult-to-machine materials)、SEE4000-A(For aluminum alloy) |

| Mitsubishi Materials | C-3SA(For aluminum alloy)、VF-6MHV(For difficult-to-machine materials) |

| MOLDINO | EPSMS-PN(General purpose)、EPPS(For general steel) |

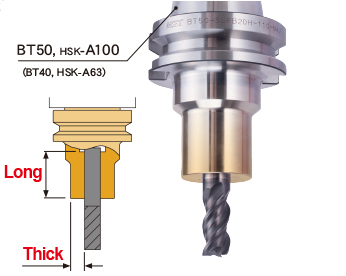

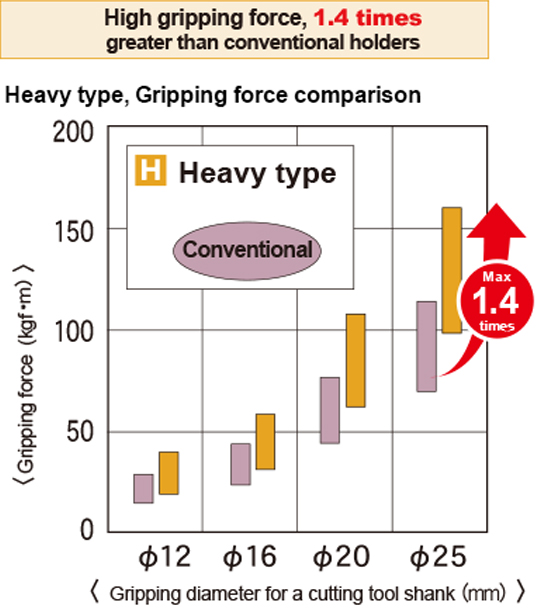

For high-torque spindle machining centers Heavy type

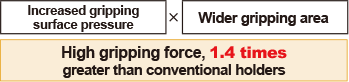

By widening the gripping area of the holder, the gripping force

increased 1.4 times higher than conventional holders.

Prevents the cutter from slipping or pulling out.